Micro Breweries

Water Treatment for Beer Brewing

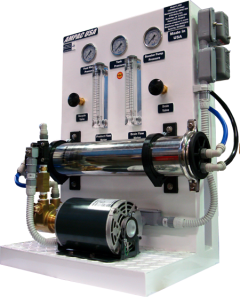

Breweries require purified water for multiple purposes inside the brewery. Boilers are used to heat mash, and boilers require purified water to prevent scaling and corrosion. For brewing, all the free chlorine must be removed to allow the yeast to work unhindered and to avoid any taste from the chlorine.To brew craft beers of particular types, certain water profiles are needed which can be created through controlling water blending. And every day in every brewery, cleaning of tanks and equipment is essential and must have clean water to be effective. Ampac can provide the water treatment advice and equipment needed for microbreweries. We have equipment installed in many local Califonia and Colorado Breweries

Breweries require purified water for multiple purposes inside the brewery. Boilers are used to heat mash, and boilers require purified water to prevent scaling and corrosion. For brewing, all the free chlorine must be removed to allow the yeast to work unhindered and to avoid any taste from the chlorine.To brew craft beers of particular types, certain water profiles are needed which can be created through controlling water blending. And every day in every brewery, cleaning of tanks and equipment is essential and must have clean water to be effective. Ampac can provide the water treatment advice and equipment needed for microbreweries. We have equipment installed in many local Califonia and Colorado Breweries

Alkaline Water Store Commercial Reverse Osmosis AP3000-LX-ALK by AMPAC USA is available at best prices and shipped swiftly. To order it today, call 909-548-4900

View detailsAMPAC USA Super Water Store Commercial Reverse Osmosis AP4000-SM is flawless for water storage applications.

View detailsCommercial Reverse Osmosis 8000 GPD, APRO8000 by AMPAC USA is perfect for meeting high pure water needs of commercial firms.

View detailsCommercial Reverse Osmosis 800 GPD APRO by AMPAC USA gets rid of all impurities & TDS issues. Get this 800 Gallons RO System cheap

View detailsCommercial Reverse Osmosis 6000 GPD, 22,750 LPD, APRO6000 by AMPAC USA is available at best prices & shipped swiftly. Call 909-548-4900.

View detailsCommercial Reverse Osmosis 3000 GPD, APRO3000 by AMPAC USA allows you to get TDS-free and contamination-free water.

View detailsBuy Commercial RO for Hotel, Business cheap. Trust Commercial Reverse Osmosis 2,200 GPD, AP2200. Call 909-548-4900.

View detailsThe AMPAC USA Commercial Reverse Osmosis 1500 GPD is the result of 20 years’ experience with the needs and requirements of commercial pure water users.

View detailsCommercial reverse osmosis 1000 GPD, APRO1000 is offered by AMPAC USA to provide pure water to commercial establishments at low costs.

View detailsWater Store Commercial Reverse Osmosis AP3000-SM by AMPAC USA lets you prepare for water every emergency.

View detailsCommercial Turnkey Brackish Reverse Osmosis 6,000 GPD, AP6000-LX by AMPAC USA gets rid of brackish water. For instant delivery of this model, call 909-548-4900.

View detailsCommercial Turnkey Brackish Reverse Osmosis 4,400 GPD by AMPAC USA allows you to get rid of brackish water in a short time span. Call 909-548-4900 to buy.

View detailsCommercial Reverse Osmosis Turnkey Brackish Water 2200 GPD, AP2200-LX is 2200 Gallon per day RO System available at best price. Call 909-548-4900 to buy.

View detailsThe AMPAC USA Fully Equipped Commercial Turnkey RO System 1500 GPD|5.7m3/day is a Turnkey Reverse Osmosis designed for Brakish and higher salt content water.

View detailsIndustrial Reverse Osmosis 20,000 GPD, AP20K-LX by AMPAC USA is suitable to serve commercial units and residential communities.

View detailsIndustrial Reverse Osmosis 12,000 GPD, AP12K-LX by AMPAC USA is fully automated and works seamlessly with minimal human supervision.

View detailsIndustrial Reverse Osmosis 10,000 GPD, AP10K-LX by AMPAC USA is automated and requires minimal human effort. Call 909-548-4900 to get it shipped instantly.

View details