Description

Industrial Reverse Osmosis (RO) Systems

Industrial Reverse Osmosis systems remove over 99% of harmful impurities and contaminants from various feed water sources. These include municipal, brackish, and surface water. The semi-permeable membrane in them blocks bacteria, particles, sugars, proteins, dyes, and other impurities that have a molecular weight of over 150-250 Dalton.

Ampac USA offers a range of custom Industrial Reverse Osmosis Systems and Commercial RO Systems to enhance water quality and remove dissolved solids and contaminants from water.

Our Standard and Custom Industrial RO systems range from 6,000 to 100,000 Gallons per day (GPD). They have selectable functional and control features to serve your reverse osmosis needs and additional apparatus supplying users the capacity to custom-make their reverse osmosis machine.

Our systems remove suspended solids from 5 to 20 microns as well as bacteria, chlorine, chemicals, organic matter, and contaminants from feed water, thus improving taste, odor, and clarity.

Since 1993, AMPAC USA has manufactured in the USA the best quality Industrial Reverse Osmosis Purification plants, advanced water treatment, and water purification systems at the best competitive price using best industrial practices and following manufacturer’s guidelines for every component, with extreme precision for custom fabrication.

Industrial Reverse Osmosis Process

Reverse Osmosis means reversing the natural process of osmosis. In osmosis, water with dissolved salt passes through a membrane from a lower salt concentration toward a higher salt concentration. This process enables plants to absorb water and its nutrients and living beings to absorb water from blood.

RO systems apply pressure using a pump to force water with impurities and ionized salts through an advanced semi-permeable membrane. The impurities in water are left behind the membrane, leaving water that is highly purified. Industrial RO systems use multiple stages, such as filters and membranes to remove a range of impurities from feedwater. They follow certain basic steps to filter water, such as:

- Two-stage prefiltration

- Reverse Osmosis

- Drainage

- Storage of purified water

Composition of Industrial RO Systems

These systems are composed of several key components that work together to ensure efficient water treatment:

- High-Pressure Pump: Supplies pressure to drive water through the RO membranes.

- Membrane Elements: Semipermeable membranes that allow water to pass but reject impurities.

- Pressure Vessels: Containers that hold membrane elements under high pressure.

- Flow and Pressure Management Devices: Instruments to monitor and regulate flow and pressure.

Specifications of Our Industrial Reverse Osmosis (RO) Systems

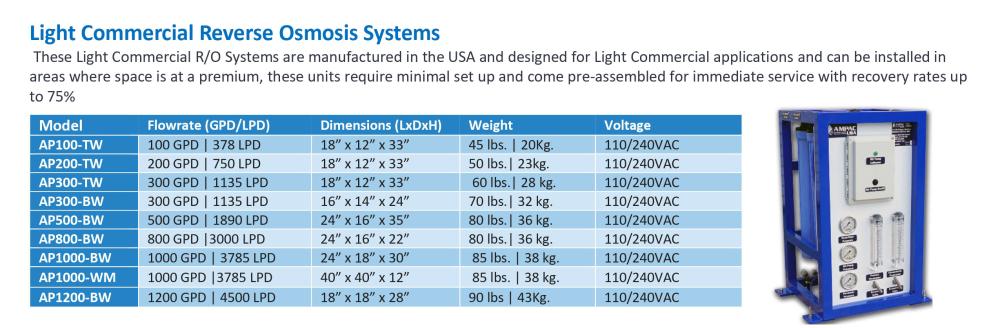

- Light Commercial RO Systems

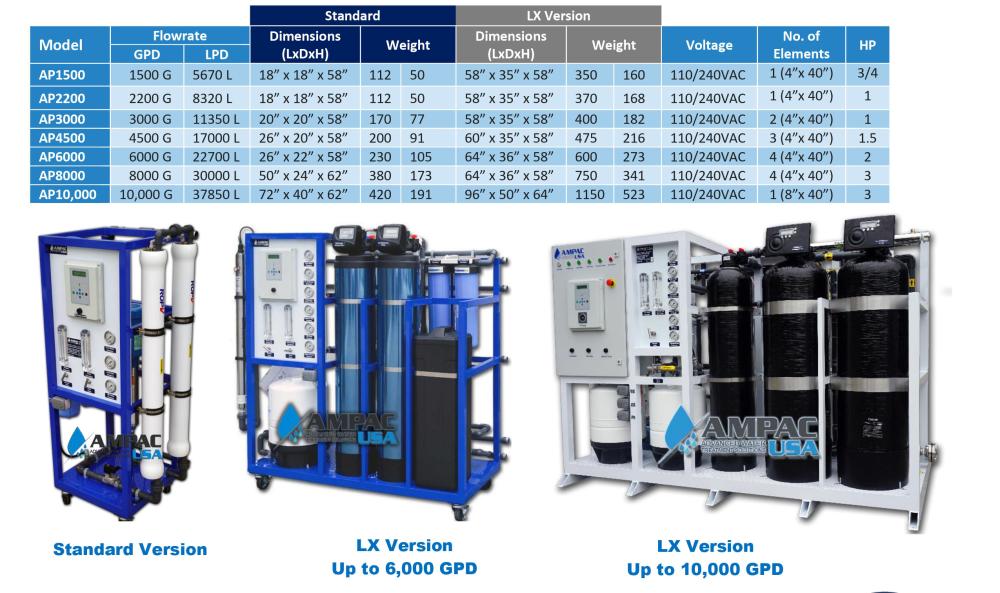

- Standard Commercial Reverse Osmosis Systems

- Industrial RO Systems Datasheet

Standard and Optional Features

Our systems have various standard and optional features for optimal water filtration. These include necessary pre-treatment, the RO process, and all post-treatment modules as per the end user's water quality analysis reports.

Reverse Osmosis Models

- Industrial Reverse Osmosis 6,000 GPD | 22.7m³/Day – 14-stage filtration, delivers 26 GPM.

- Industrial Reverse Osmosis 8,000 GPD | 30.2m³/Day – PLC controlled, 12-stage filtration.

- Mobile Turnkey Reverse Osmosis 10,000 GPD | 37.9m³/Day – 14-stage filtration, PLC equipped.

- Industrial Reverse Osmosis 30,000 GPD | 4.75m³/hr – Pre-treatment module, aluminum skid.

- Industrial Reverse Osmosis 60,000 GPD | 9.5m³/hr – Advanced membranes, 50–75% recovery rate.

- Mobile Turnkey RO 80,000 GPD | 12.6m³/hr – Fully automated, PLC controlled, NSF/WQA/ISO certified.

Applications of Industrial RO Systems

General Applications

- Seawater desalination (especially MENA regions)

- Drinking water purification (home and office)

- Wastewater treatment

- Ultrapure water production

Domain-specific Applications

- Power generation

- Pharmaceuticals

- Petrochemicals

- Manufacturing

- Food and beverage

- Automotive

- Horticulture

- Restaurants

- Hospitals

Applications