Last updated on January 12th, 2026 at 01:11 pm

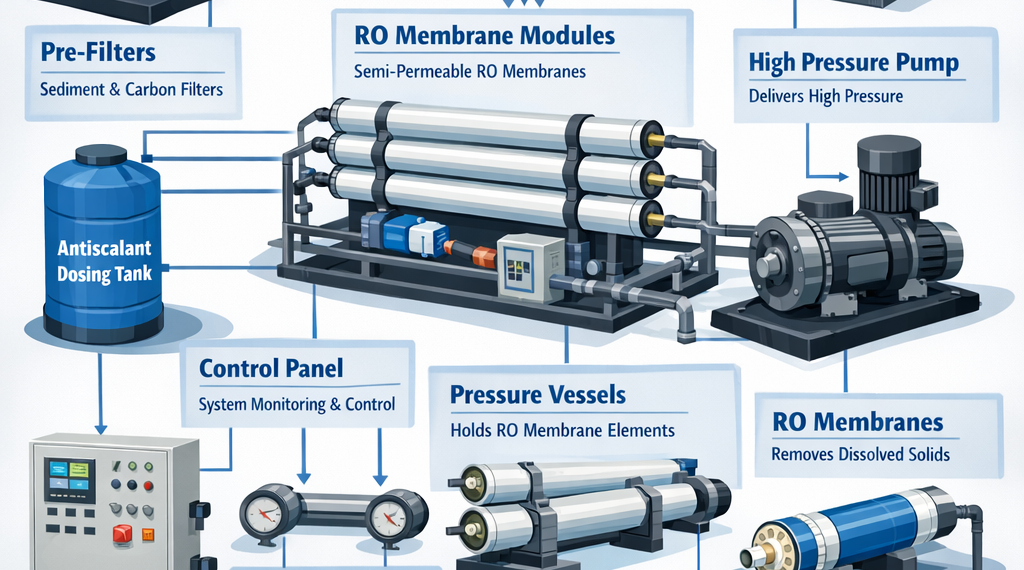

An industrial reverse osmosis (RO) system is an integrated water treatment solution built from multiple engineered components working together to deliver consistent, high-purity water. Each component plays a critical role in system efficiency, membrane protection, operating cost, and long-term reliability.

Understanding industrial RO system components is essential for proper system selection, operation, and maintenance, especially in continuous industrial environments where downtime is costly.

This guide breaks down every major component used in modern industrial RO plants and explains why each component matters.

Industrial RO System Components – Feed Water Intake and Raw Water Handling

Source Water Entry and Initial Screening

Industrial RO systems typically treat water sourced from:

-

Municipal supply

-

Borewell or groundwater

-

Surface water

-

Seawater or brackish water

Before entering the pre-treatment section, raw water passes through basic screening or strainers to remove large debris and prevent mechanical damage to downstream equipment.

Read more: Industrial Reverse Osmosis Systems & Water Treatment Systems

Pre-Treatment Systems in Industrial RO Plants

Multimedia Sand Filters

Multimedia filters remove suspended solids, turbidity, and particulate matter from feed water. These filters protect RO membranes by reducing fouling potential and improving system stability.

Key benefits:

-

Improved membrane life

-

Reduced pressure drop

-

Stable permeate flow

Activated Carbon Filters

Activated carbon filters remove:

-

Free chlorine

-

Organic compounds

-

Odor and color

Chlorine removal is critical, as chlorine can irreversibly damage RO membranes if not properly removed.

Water Softeners

Water softeners reduce hardness by removing calcium and magnesium ions. This minimizes scaling on RO membranes and improves recovery rates in high-hardness water applications.

Cartridge Filters

Cartridge filters provide fine filtration (typically 1–5 microns) before water enters the RO membranes. They act as the final physical barrier against suspended particles.

Read More: How Industrial Wastewater Affects Clean Water Sources

High-Pressure Pump Systems

Role of High-Pressure Pumps in Industrial RO

High-pressure pumps provide the driving force required to push water through semi-permeable RO membranes. The pump must overcome the osmotic pressure of the feed water, which varies based on TDS levels.

Pump Selection Considerations

Key factors include:

-

Feed water salinity

-

Required operating pressure

-

Flow rate

-

Energy efficiency

Efficient pump selection significantly impacts overall operating cost and energy consumption.

Reverse Osmosis Membranes and Pressure Vessels

Industrial RO Membranes

Industrial RO membranes are the heart of the system. Most industrial systems use Thin Film Composite (TFC) membranes due to their high rejection rates and durability.

Membranes remove:

-

Dissolved salts

-

Heavy metals

-

Bacteria and microorganisms

-

Organic contaminants

Pressure Vessels

Pressure vessels house RO membranes and are designed to withstand high operating pressures. They are typically constructed from fiberglass-reinforced plastic (FRP) or stainless steel, depending on application and water chemistry.

Read more: Industrial Carbon Water Filtration: The Ultimate Solution for Pure and Safe Water

RO Skid and Piping Assembly

Skid-Mounted System Design

Industrial RO systems are often skid-mounted, allowing:

-

Compact installation

-

Faster commissioning

-

Easier transportation

Skid systems integrate pumps, membranes, piping, and instrumentation into a single engineered platform.

High-Grade Piping and Valves

Piping materials are selected based on:

-

Pressure rating

-

Corrosion resistance

-

Chemical compatibility

Proper piping design ensures leak-free operation and system longevity.

Instrumentation and Monitoring Devices

Pressure Gauges and Flow Meters

These devices monitor:

-

Feed pressure

-

Permeate flow

-

Reject flow

They provide immediate insight into system health and performance trends.

Read More – Importance of Industrial RO Water Purifiers in Power Plants

Conductivity and TDS Sensors

Conductivity sensors measure permeate water quality and help detect membrane damage or performance decline in real time.

Control Panels and Automation Systems

PLC-Based Control Panels

Programmable Logic Controllers (PLC) automate:

-

System startup and shutdown

-

Alarm handling

-

Safety interlocks

Automation reduces human error and improves operational reliability.

SCADA Integration

Advanced industrial RO systems integrate with SCADA platforms for:

-

Remote monitoring

-

Data logging

-

Predictive maintenance

Chemical Dosing Systems

Antiscalant Dosing Units

Antiscalants prevent mineral scaling on RO membranes, especially in high-recovery systems.

pH Adjustment Systems

pH correction improves membrane performance and protects system components from corrosion or scaling.

Clean-In-Place (CIP) System

Purpose of CIP in Industrial RO

CIP systems restore membrane performance by removing fouling and scaling through controlled chemical cleaning.

When CIP Is Required

Indicators include:

-

Increased pressure drop

-

Reduced permeate flow

-

Declining salt rejection

A properly designed CIP system extends membrane life and maintains stable performance.

Permeate Storage and Post-Treatment (Optional)

Permeate Tanks

Treated water is stored in permeate tanks for:

-

Process usage

-

Distribution

-

Further polishing

Post-Treatment Options

Depending on application, post-treatment may include:

-

UV disinfection

-

Polishing filters

-

Mineral adjustment

Why Component Quality Matters in Industrial RO Systems

Impact on Performance and Cost

High-quality components:

-

Reduce maintenance frequency

-

Lower operating costs

-

Improve system uptime

-

Extend membrane lifespan

Inferior components often lead to premature failures, higher energy consumption, and inconsistent water quality.

Why Choose AMPAC USA?

AMPAC USA stands out as a trusted leader in advanced water treatment solutions, offering high-quality industrial and commercial reverse osmosis systems designed for performance, reliability, and long-term value. With cutting-edge engineering, robust components, customizable systems, and exceptional after-sales support, AMPAC USA ensures cleaner water, improved efficiency, and cost-effective operation for every application.

References:

-

Water Quality Association (WQA) – Industrial RO component standards

-

American Water Works Association (AWWA) – Water treatment engineering practices

-

RO membrane manufacturers’ technical documentation