Clean water is one of the most essential resources for sustaining life, ecosystems, and economic development. Yet, industrial wastewater has emerged as one of the leading threats to maintaining the purity of rivers, lakes, groundwater, and other freshwater systems. As industries expand, their operations often release contaminated effluents filled with toxic chemicals, heavy metals, and biological pollutants that disrupt the natural balance of clean water sources. Understanding how industrial wastewater affects clean water sources is crucial for creating sustainable practices, protecting ecosystems, and ensuring safe water for future generations.

The Nature of Industrial Wastewater

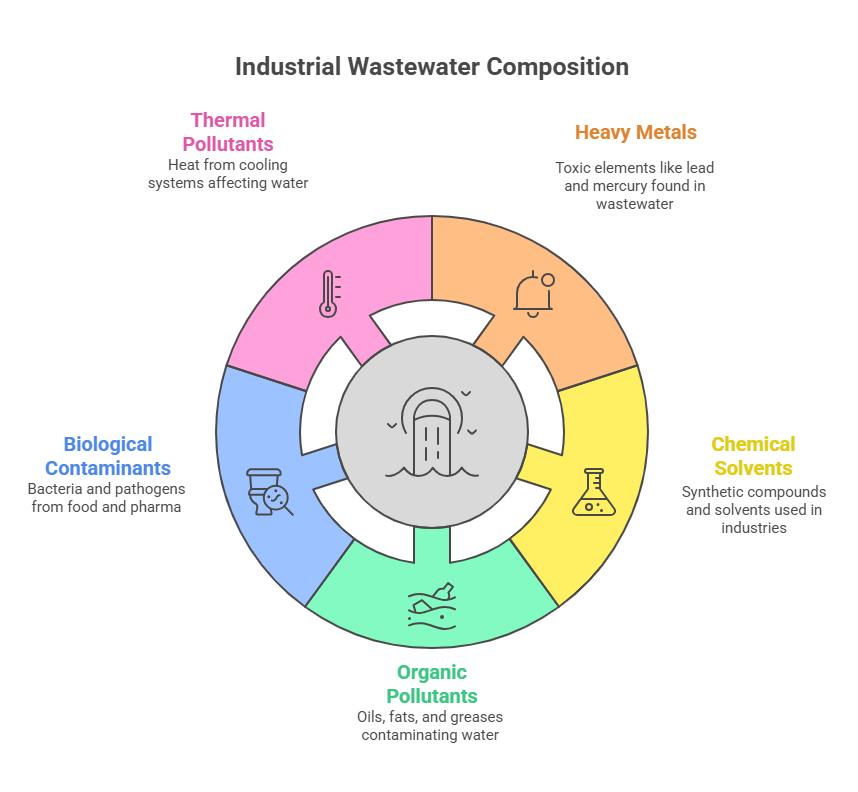

Industrial wastewater refers to any liquid waste generated by industrial activities, including manufacturing, mining, chemical processing, textiles, power generation, and food production. Unlike domestic sewage, industrial wastewater often contains complex mixtures of hazardous materials, such as:

- Heavy metals like lead, mercury, cadmium, and arsenic.

- Chemical solvents and synthetic compounds.

- Organic pollutants including oils, fats, and greases.

- Biological contaminants from food and pharmaceutical industries.

- Thermal pollutants caused by water used in cooling systems.

The composition of industrial wastewater depends on the specific processes within an industry, but nearly all forms pose risks to clean water supplies if discharged without treatment.

Pathways of Contamination

Industrial wastewater can infiltrate clean water sources through several pathways:

- Direct Discharge into Waterways – Factories and plants may release untreated or partially treated effluents directly into rivers, streams, and lakes.

- Seepage into Groundwater – Contaminants percolate through soil layers, entering underground aquifers and wells.

- Surface Runoff – During heavy rains, contaminated wastewater stored in open lagoons or tanks may overflow into nearby water bodies.

- Accidental Spills – Industrial accidents or equipment failures can release large amounts of wastewater suddenly into the environment.

These pathways result in long-term accumulation of pollutants, making it increasingly difficult to restore water purity.

Impact on Freshwater Ecosystems

Industrial wastewater severely disrupts natural aquatic ecosystems. The toxic load of contaminants can cause:

- Loss of biodiversity: Many aquatic species, including fish, amphibians, and invertebrates, cannot tolerate high levels of heavy metals or chemical toxins.

- Oxygen depletion: Organic matter from wastewater consumes dissolved oxygen during decomposition, suffocating aquatic life.

- Eutrophication: Nutrient-rich wastewater (containing nitrogen and phosphorus) triggers uncontrolled algae blooms that block sunlight and deplete oxygen levels.

- Bioaccumulation: Toxic substances accumulate in organisms, moving up the food chain and impacting predators, including humans.

This chain reaction leads to ecosystem collapse, where once-thriving freshwater systems become lifeless or dominated by harmful organisms.

Human Health Consequences

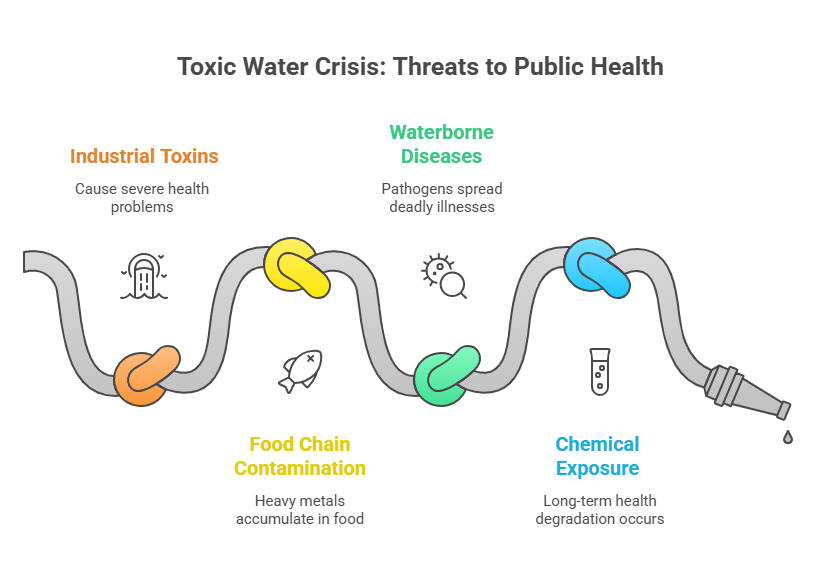

The contamination of clean water sources by industrial wastewater poses direct and indirect threats to human health:

- Drinking Water Pollution – Communities relying on rivers, lakes, or groundwater near industrial sites face exposure to toxins like lead and arsenic, causing neurological damage, kidney disorders, and cancer.

- Food Chain Contamination – Fish and crops irrigated with polluted water accumulate heavy metals, which then enter human diets.

- Waterborne Diseases – Wastewater laden with pathogens contributes to outbreaks of diseases such as cholera, typhoid, and hepatitis.

- Chemical Exposure – Long-term ingestion of trace industrial chemicals leads to chronic illnesses, reproductive disorders, and developmental issues in children.

Thus, industrial wastewater not only affects the environment but also undermines public health on a massive scale.

Economic Implications

The economic costs of contaminated clean water sources are substantial:

- Increased water treatment costs for municipalities that must remove industrial pollutants before supplying drinking water.

- Loss of fisheries and aquaculture due to toxic contamination of rivers and lakes.

- Decline in agriculture when polluted water is used for irrigation, reducing crop yields and soil quality.

- Healthcare costs associated with waterborne diseases and chemical poisoning.

- Tourism impacts, as polluted rivers and lakes deter visitors and harm recreation-based economies.

The global economy pays billions annually for the consequences of industrial water pollution, making prevention and treatment more cost-effective than neglect.

Heavy Metals: The Silent Threat

Among industrial wastewater pollutants, heavy metals pose a particularly dangerous and persistent threat. Unlike organic pollutants that may degrade over time, heavy metals such as lead, mercury, cadmium, and chromium remain in the environment indefinitely. They bind to sediments, infiltrate aquatic food chains, and accumulate in living organisms. Even at low concentrations, these metals cause:

- Neurological damage

- Kidney and liver dysfunction

- Respiratory complications

- Cancers and genetic mutations

The persistence and toxicity of heavy metals make them one of the most pressing issues in controlling industrial wastewater impacts.

Case Studies of Industrial Wastewater Pollution

- Textile Industry Discharge – Dyes, bleaching agents, and detergents from textile factories release harmful chemicals into rivers, altering pH levels and rendering water unsafe for consumption or irrigation.

- Mining Operations – Acid mine drainage releases sulfuric acid and dissolved metals, devastating freshwater ecosystems and contaminating groundwater.

- Chemical Manufacturing – Factories producing plastics, pesticides, and fertilizers often release toxic byproducts that persist in water sources for decades.

- Thermal Power Plants – Heated wastewater alters river temperatures, reducing oxygen levels and disrupting aquatic life cycles.

These real-world examples highlight how diverse industrial sectors contribute to widespread freshwater contamination.

Regulatory Challenges

While many nations have established regulations governing industrial wastewater discharge, enforcement remains inconsistent. Key challenges include:

- Weak monitoring systems that fail to detect unauthorized discharges.

- Corruption and lack of compliance, where industries bypass environmental rules.

- Outdated infrastructure in developing countries, lacking modern wastewater treatment facilities.

- Rising industrial demand that overwhelms existing environmental controls.

Without strong regulation and strict compliance, industrial wastewater continues to degrade global clean water resources.

Advanced Industrial Wastewater Treatment Technologies

Physical Treatment Methods

Physical processes are the first line of defense against water pollution. These methods separate suspended solids, oils, and large contaminants from wastewater before it enters biological or chemical treatment phases.

- Sedimentation tanks allow heavy particles to settle at the bottom.

- Oil-water separators remove oils and greases, which are common in petroleum and food industries.

- Filtration systems trap micro-particles, improving water clarity before further treatment.

Chemical Treatment Methods

Chemicals are used to neutralize toxins, eliminate pathogens, and remove dissolved pollutants.

- Coagulation and flocculation bind fine particles into larger clumps that can be filtered easily.

- Neutralization tanks balance acidic or alkaline wastewater from chemical plants.

- Advanced oxidation processes (AOPs) use ozone, hydrogen peroxide, or UV light to destroy complex organic pollutants.

Biological Treatment Methods

Microorganisms play a vital role in breaking down organic waste.

- Activated sludge systems use bacteria to consume organic matter, reducing oxygen demand in receiving waters.

- Trickling filters spread wastewater over stones or plastic media where microbes thrive and degrade pollutants.

- Anaerobic digesters convert organic matter into methane gas, which can be used as renewable energy.

Membrane Technologies

Membrane-based treatments provide high-quality water recovery by filtering out even the smallest contaminants.

- Reverse Osmosis (RO) removes dissolved salts, heavy metals, and chemical impurities.

- Ultrafiltration and nanofiltration act as barriers against pathogens and suspended solids.

- Forward osmosis offers energy-efficient treatment with lower operational costs.

Zero Liquid Discharge (ZLD) Systems

ZLD ensures that no wastewater leaves the facility. Industries recycle and reuse all water, producing only solid residues. Though expensive, ZLD is crucial for industries in water-scarce regions and those generating highly toxic effluents.

These solutions require investment but significantly reduce the environmental footprint of industries.

Global Call for Sustainable Practices

To preserve clean water sources, industries must adopt sustainable water management practices:

- Reduce water consumption through recycling and process optimization.

- Adopt cleaner production methods that minimize pollutant generation.

- Invest in wastewater treatment infrastructure with cutting-edge technologies.

- Comply with international standards for discharge and reporting.

- Collaborate with governments and communities to restore contaminated ecosystems.

A global commitment to sustainability ensures that industrial growth does not come at the expense of clean water security.

AMPAC USA’s Industrial Wastewater Treatment Solutions are engineered to deliver unmatched efficiency, reliability, and sustainability. Designed to tackle the toughest contaminants—ranging from heavy metals and toxic chemicals to oils and organic waste—our systems ensure that industrial effluents are treated to meet the highest environmental standards. With advanced technologies such as reverse osmosis, ultrafiltration, and zero-liquid discharge systems, we help industries minimize water consumption, reduce environmental impact, and achieve compliance with strict regulatory requirements. Whether it’s for manufacturing, mining, food processing, or chemical plants, AMPAC USA provides customized, high-performance solutions that transform wastewater into a valuable resource, safeguarding both your operations and our planet’s clean water future.