Access to pure, safe, and reliable water is a cornerstone of industrial success. Industries such as food and beverage, pharmaceuticals, power generation, electronics, and oil and gas rely heavily on water quality. In this context, industrial reverse osmosis (RO) treatment has emerged as a critical solution for producing pure water at scale. This advanced technology ensures consistent water quality, protects expensive equipment, reduces operational costs, and complies with strict regulatory standards.

Understanding Industrial Reverse Osmosis Treatment

Reverse Osmosis (RO) is a process that uses a semi-permeable membrane to remove dissolved salts, impurities, and contaminants from water. In an industrial setting, reverse osmosis systems are scaled up with high-capacity pumps, membranes, and pre-treatment equipment to handle massive volumes of water. These systems deliver ultra-pure water suitable for highly demanding industrial processes.

Unlike conventional filtration, which only removes particles, RO eliminates dissolved solids, bacteria, viruses, heavy metals, and organic impurities, ensuring the highest level of water purity.

The Importance of Pure Water in Industrial Operations

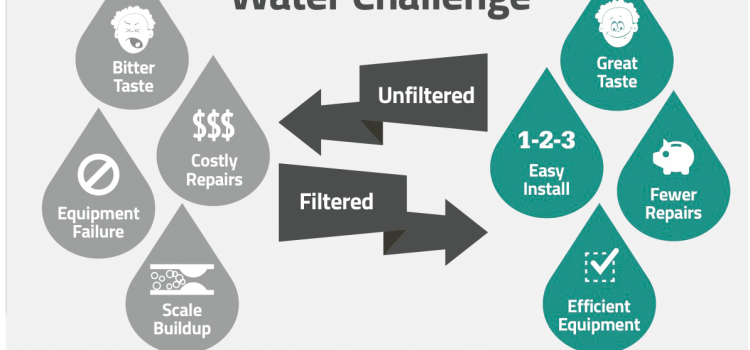

1. Protection of Equipment and Infrastructure

Hard water and dissolved minerals lead to scaling, corrosion, and fouling in boilers, heat exchangers, and pipelines. This shortens equipment lifespan and increases downtime. Industrial RO treatment prevents mineral buildup, ensuring smooth operation and reducing costly repairs.

2. Compliance With Industry Standards

Industries like pharmaceuticals and electronics must meet stringent purity standards, such as USP, ISO, and ASTM guidelines. RO-treated water provides consistent compliance, helping businesses avoid penalties and reputational risks.

3. Optimizing Production Quality

In food and beverage production, water quality directly impacts taste, safety, and shelf life. Similarly, in pharmaceuticals, ultrapure water is essential for drug formulation. Industrial RO treatment guarantees stable and high-quality output across production lines.

4. Cost Efficiency and Sustainability

By reducing reliance on chemical treatments and lowering energy consumption in downstream systems, RO minimizes operational expenses. Additionally, RO supports sustainability goals by enabling water reuse and reducing wastewater discharge.

How Industrial Reverse Osmosis Systems Work

The functioning of an industrial RO system involves multiple stages designed to protect membranes and deliver the highest quality water:

- Pre-Treatment Stage

- Water passes through sand filters, activated carbon filters, and water softeners.

- Removes suspended solids, chlorine, and hardness that could damage RO membranes.

- High-Pressure Pumping

- A high-pressure pump forces water through the RO membranes, overcoming osmotic pressure.

- Membrane Filtration

- Semi-permeable membranes remove dissolved salts, organics, and microorganisms.

- Produces two streams: permeate (pure water) and concentrate (rejected brine).

- Post-Treatment

- Additional processes such as UV disinfection, pH adjustment, and remineralization ensure water meets specific industrial requirements.

- Storage and Distribution

- Purified water is stored in sanitized tanks and distributed through pipelines with safeguards against recontamination.

Key Applications of Industrial Reverse Osmosis

1. Power Plants

Power plants use RO-treated water in boilers and cooling towers, preventing scale and corrosion while improving efficiency.

2. Food and Beverage Industry

Breweries, dairies, and bottling plants rely on RO to ensure taste consistency and safety in products.

3. Pharmaceutical and Biotechnology

RO water is vital for drug manufacturing, laboratory use, and sterile environments, ensuring compliance with global pharmacopeia standards.

4. Electronics and Semiconductor Manufacturing

Ultra-pure water is essential for microchip production and precision cleaning. RO ensures zero ionic contamination.

5. Oil and Gas Industry

Refineries and petrochemical plants use RO for boiler feedwater, process water, and desalination, reducing dependence on freshwater sources.

Benefits of Industrial Reverse Osmosis Treatment

Unmatched Purity

RO achieves up to 99% rejection of dissolved salts and impurities, ensuring water quality beyond conventional treatment methods.

Operational Reliability

Stable water quality minimizes process interruptions and ensures compliance with stringent industrial standards.

Reduced Chemical Usage

RO reduces reliance on harsh chemicals for water conditioning, cutting environmental impact and operational costs.

Water Reuse and Conservation

Industries can recycle wastewater through RO, aligning with sustainability initiatives and reducing freshwater withdrawals.

Scalability

Industrial RO systems can be customized for small-scale plants or large manufacturing facilities, adapting to evolving demands.

Challenges and Solutions in Industrial RO Systems

While industrial RO systems offer unmatched advantages, certain challenges must be addressed:

- Membrane Fouling: Caused by suspended solids, biological growth, and scaling.

- Solution: Effective pre-treatment, anti-scalants, and regular cleaning cycles.

- High Energy Consumption: Pressure pumps consume significant energy.

- Solution: Adoption of energy recovery devices and advanced membrane technologies.

- Wastewater Disposal: RO produces concentrated brine that requires proper management.

- Solution: Brine minimization, zero-liquid discharge systems, and recycling technologies.

Technological Innovations in Industrial RO Systems

The evolution of industrial reverse osmosis technology has led to advanced systems with higher efficiency and lower costs:

- Energy Recovery Devices (ERDs) to reduce power consumption.

- Nanocomposite Membranes for higher rejection rates and durability.

- Automation and IoT Integration for real-time monitoring and predictive maintenance.

- Hybrid Systems combining RO with ultrafiltration, EDI (electrodeionization), and nanofiltration.

These innovations make RO systems more cost-effective, sustainable, and adaptable for future industrial needs.

Why Industries Must Prioritize RO Treatment

The growing demand for high-quality water, coupled with environmental concerns and stricter regulations, makes industrial RO treatment non-negotiable. Companies that invest in RO systems enjoy:

- Consistent compliance with international standards.

- Lower operating costs through reduced maintenance and energy efficiency.

- Enhanced product quality across industries.

- Long-term sustainability benefits by conserving water resources.

Conclusion

Industrial reverse osmosis treatment is the backbone of modern water purification strategies in industries worldwide. Its ability to deliver pure, reliable, and sustainable water supply ensures operational efficiency, compliance, and cost savings. From pharmaceuticals and electronics to power plants and food processing, RO technology safeguards both production and profitability.

As industries continue to evolve, the reliance on industrial reverse osmosis systems will only increase, positioning it as an essential solution for maintaining pure water supply in the modern era.