Last updated on September 16th, 2025 at 02:30 pm

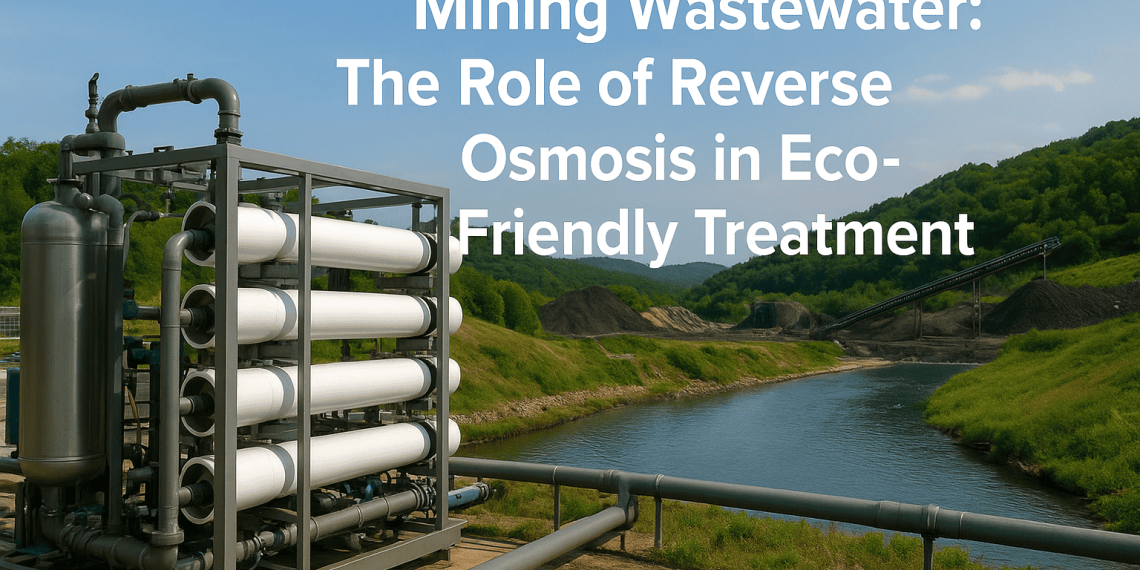

Mining is one of the world’s most resource-intensive industries. While it drives economic growth, it also generates a substantial environmental footprint, particularly through wastewater discharge. Mining wastewater often contains heavy metals, sulfates, acids, and dissolved solids that can contaminate natural ecosystems if left untreated. With increasing regulatory scrutiny and environmental awareness, the need for eco-friendly wastewater treatment solutions has become urgent. Among the most effective technologies available, Reverse Osmosis (RO) stands out as a sustainable and highly efficient treatment method.

In this article, we will explore the challenges of mining wastewater, the limitations of conventional treatment methods, and the critical role of Reverse Osmosis in ensuring environmentally safe discharge and water reuse.

Understanding the Problem: Mining Wastewater Composition

Mining operations involve processes such as ore extraction, mineral processing, and equipment cooling, all of which consume significant water volumes. The wastewater generated from these activities often contains:

- Acid Mine Drainage (AMD): Sulfide minerals exposed to oxygen and water form sulfuric acid, leading to acidic wastewater.

- Heavy Metals: Arsenic, lead, mercury, cadmium, and nickel are frequently detected.

- Suspended Solids and Turbidity: Fine particles from crushed rock and soil.

- Salts and Dissolved Solids: Elevated levels of TDS (total dissolved solids) make the water unfit for discharge or reuse.

- Cyanides and Chemicals: From gold leaching and flotation processes.

These pollutants make mining wastewater highly toxic. Left untreated, it can destroy aquatic life, contaminate groundwater, and threaten human health.

Limitations of Conventional Treatment Methods

For decades, the mining industry has relied on traditional wastewater treatment processes. However, these methods are often insufficient for modern environmental standards.

- Chemical Precipitation:

While effective for removing some metals, this process generates large amounts of sludge, which itself requires disposal. - Neutralization and Sedimentation:

Useful for acidity control but unable to reduce dissolved salts and toxic metals completely. - Evaporation Ponds:

High land usage and risk of seepage make them unsustainable in the long term. - Biological Treatment:

Limited efficiency in handling high concentrations of heavy metals and extreme pH conditions.

These methods typically shift the problem rather than solve it, creating secondary waste streams. This is where Reverse Osmosis provides a breakthrough.

The Role of Reverse Osmosis in Mining Wastewater Treatment

Reverse Osmosis (RO) is a membrane filtration process that separates contaminants from water by applying pressure across a semi-permeable membrane. The result is two distinct streams:

- Permeate (clean water): Safe for reuse or discharge.

- Concentrate (reject stream): Containing concentrated contaminants for controlled disposal.

Key Advantages of RO in Mining Applications

- High Removal Efficiency:

RO membranes can remove up to 99% of dissolved salts, heavy metals, and suspended solids, producing high-quality effluent. - Acid Mine Drainage Treatment:

RO is highly effective in neutralizing the impact of acidic mine drainage, making it a sustainable solution for mines facing severe AMD issues. - Water Reuse and Recycling:

Treated water can be reused in mineral processing, dust suppression, or cooling, significantly reducing freshwater demand. - Compliance with Stringent Standards:

RO-treated water meets or exceeds EPA and international discharge regulations, ensuring environmental safety. - Compact and Scalable Systems:

RO plants are modular and can be customized to handle different flow rates, making them suitable for small mines or large-scale operations.

Reverse Osmosis Process Flow in Mining Wastewater

The RO treatment for mining wastewater typically involves multiple steps:

- Pre-Treatment:

- Screening to remove large solids.

- Chemical dosing for pH adjustment.

- Media filtration or ultrafiltration to protect RO membranes.

- Primary RO Filtration:

- High-pressure pumps force water through membranes.

- Contaminants are rejected, and permeate is collected.

- Brine Management:

- Concentrated reject water may be directed to evaporation ponds, crystallizers, or zero liquid discharge (ZLD) systems.

- Post-Treatment:

- Final polishing, disinfection, or remineralization for reuse in industrial processes.

This flow ensures maximum recovery, reduced sludge, and minimized environmental risks.

Eco-Friendly Benefits of Reverse Osmosis

1. Reduction in Freshwater Withdrawal

Mining operations are often located in arid regions where water scarcity is a challenge. RO enables wastewater recycling, reducing dependence on freshwater sources.

2. Minimal Chemical Usage

Unlike chemical precipitation methods, RO does not require large volumes of reagents, making it cleaner and safer for the environment.

3. Lower Carbon Footprint

Modern RO systems are energy-efficient, especially when combined with energy recovery devices and renewable energy sources.

4. Sustainable Brine Management

Concentrate streams can be treated with advanced ZLD technologies, reducing the risk of soil and groundwater contamination.

Challenges of Implementing Reverse Osmosis in Mining

While RO offers significant advantages, certain challenges must be addressed for optimal performance:

- High Energy Requirements: Pressurizing water for RO membranes consumes energy. However, innovations in pump design and recovery systems are lowering costs.

- Membrane Fouling and Scaling: Pre-treatment is essential to prevent fouling from suspended solids, silica, and scaling salts.

- Brine Disposal: Managing concentrated reject streams requires careful planning and sustainable solutions.

- Capital Investment: Initial setup costs can be high, but long-term operational savings justify the investment.

Case Applications of RO in Mining Wastewater

- Gold Mining Operations:

Cyanide-laden wastewater is treated with RO after pre-treatment, ensuring safe discharge and reuse in leaching processes. - Coal Mines:

Acid mine drainage is neutralized, filtered, and treated through RO to remove sulfates and metals, preventing river contamination. - Copper Mines:

RO enables recovery of process water while isolating dissolved copper and other metals for safer handling.

These applications highlight RO’s versatility across diverse mining sectors.

The Future of Eco-Friendly Mining Wastewater Treatment

As sustainability becomes central to mining operations, Reverse Osmosis will play a defining role in the industry’s environmental strategy. Emerging trends include:

- Hybrid Systems: Combining RO with nanofiltration, ion exchange, and biological treatment for maximum efficiency.

- Zero Liquid Discharge (ZLD): Full water recovery and crystallization of salts for resource recovery.

- Smart Monitoring Systems: IoT-enabled RO plants that optimize energy usage, membrane life, and recovery rates.

- Integration with Renewable Energy: Solar- and wind-powered RO systems for off-grid mining operations.

Conclusion

Mining wastewater presents one of the most pressing environmental challenges of our time. Traditional methods alone are no longer sufficient to meet stringent environmental standards. Reverse Osmosis has emerged as a critical technology, capable of transforming contaminated mining effluent into reusable, eco-friendly water. By reducing freshwater consumption, minimizing pollution, and ensuring compliance, RO empowers the mining industry to operate more responsibly and sustainably.

The adoption of Reverse Osmosis is not just an operational choice—it is a commitment to environmental stewardship, regulatory compliance, and the sustainable future of mining.

AMPAC USA: Leading the Charge in Reverse Osmosis for Mining

AMPAC USA stands out as a trailblazer in offering top-notch reverse osmosis systems tailor-made for the mining sector. Our cutting-edge solutions have been pivotal in addressing the distinct requirements of mining wastewater. Our blend innovations with eco-friendly approaches to offer systems that not only effectively treat wastewater but also significantly reduce the environmental impact. Our commitment to quality and sustainability makes them an ideal partner for mining industries aiming for responsible water treatment solutions.